Product

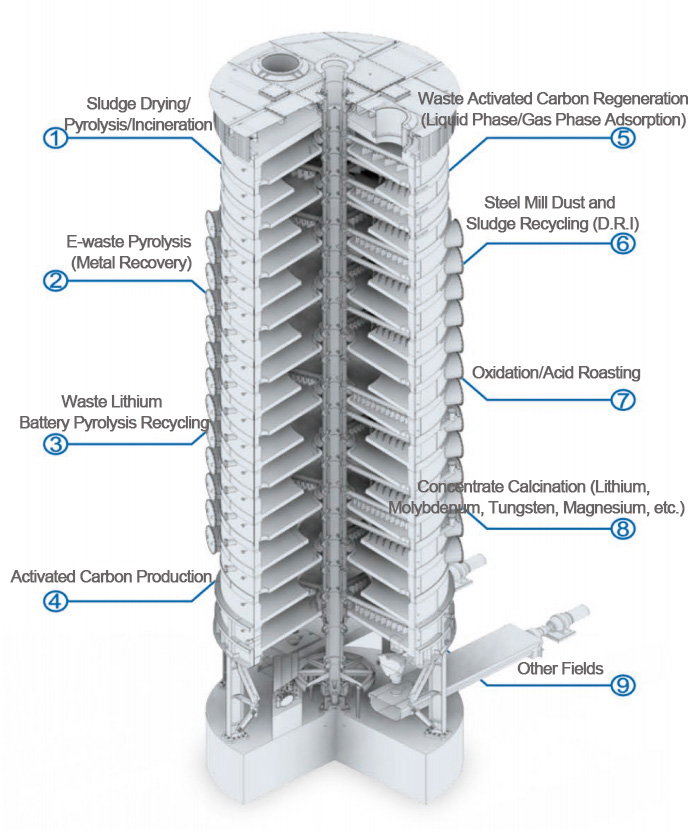

Multiple Hearth Furnace (MHF)

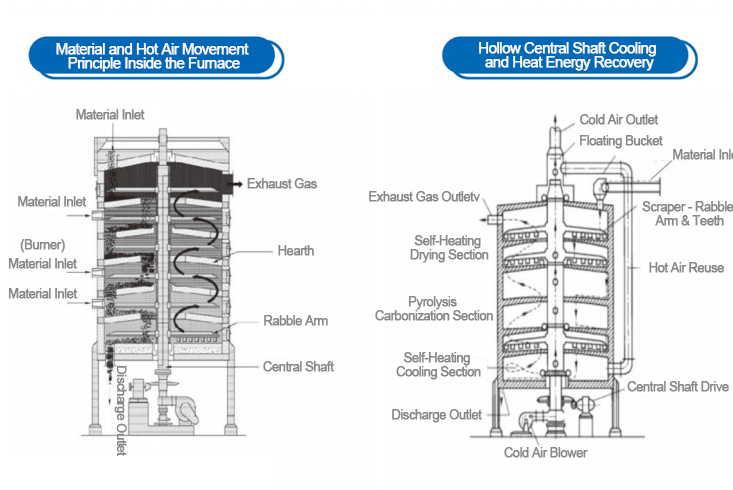

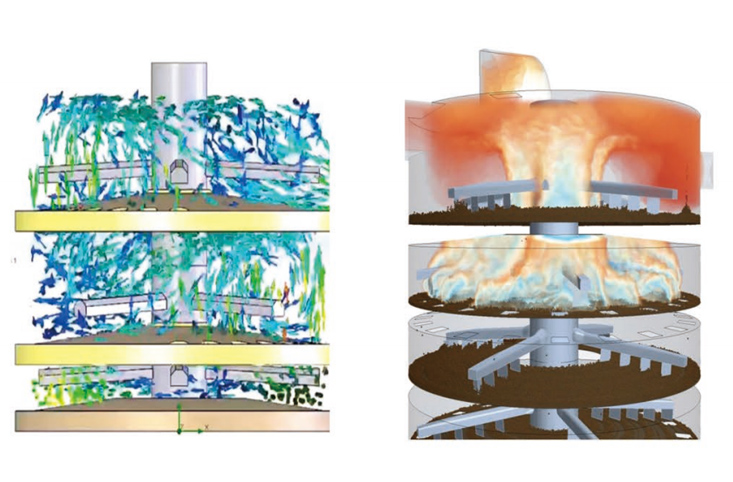

1. Reaction gas can be introduced at different positions, each hearth layer's temperature can be precisely and independently controlled

2. Reaction atmosphere (Oxidizing/Reducing/Inert, etc.) and time are controllable, fully automated control

3. Strong temperature adjustability, achieving a distribution close to the ideal furnace temperature curve

4. Good sealing performance, oxygen content can be controlled to <1%

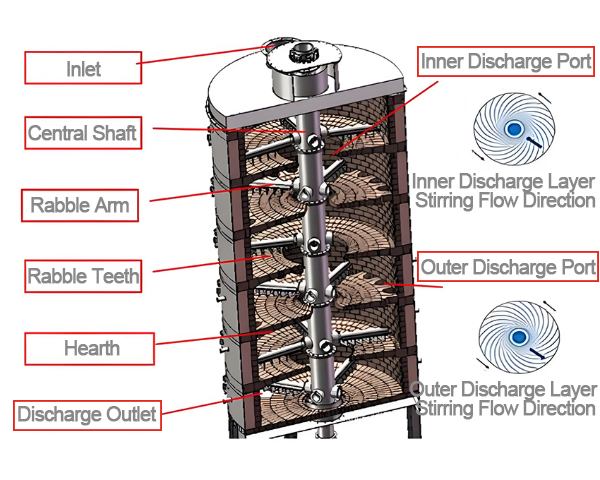

5. Low-speed gentle stirring and turning ensures uniformity, low wear, less flue gas, and low dust

6. Material movement speed on the hearth and residence time in the furnace can be adjusted by changing the number of rabble arms/teeth and adjusting the central shaft rotation speed

7. Vertical structure, small footprint, large single-unit processing capacity

8. Large contact area between flue gas and material, high heat exchange efficiency

| Layered Temperature Control | Low Power Consumption | Excellent Gas Tightness |

| Layered Atmosphere Control | Long Service Life | Low Heat Loss |

| Multiple Operation Modes |

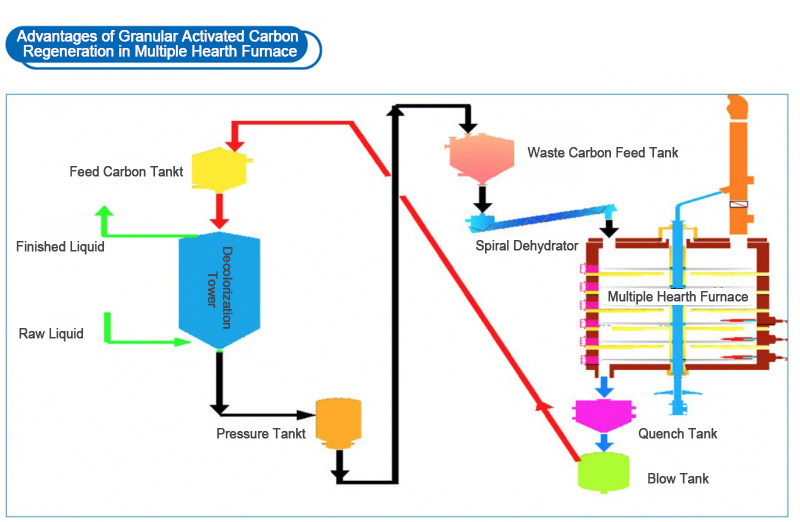

Waste Heat Recovery: Can recover 1 ton of saturated steam at 5kg pressure per ton of carbon regenerated.

Low Fuel Consumption: Consumes 150 Nm³ of natural gas to regenerate 1 ton of activated carbon.

Afterburner Fuel Consumption: 150 Nm³ per ton of activated carbon (Natural Gas 850°C)

Low wear and consumption of activated carbon;

Low risk of mechanical failure;

High activated carbon conveying efficiency (high solid-liquid ratio)

We guarantee an activated carbon loss rate of approximately 5-8% during the regeneration process.We guarantee an activated carbon loss rate of approximately 5-8% during the regeneration process.