Product

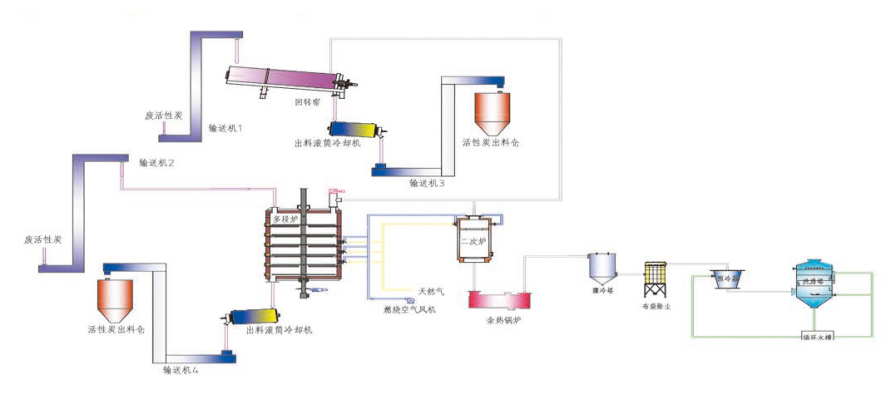

Activated Carbon Recycling System (On-site Regeneration / Off-site Green Island Center)

Regeneration in activated carbon decolorization fields.

Construction of waste activated carbon regeneration centers (liquid phase adsorption carbon / VOC adsorption carbon)

On-site regeneration of waste activated carbon.

Pairing with upstream wastewater adsorption processes to form continuous adsorption-regeneration systems for wastewater applications. 5. Combining with upstream decolorization processes to form continuous decolorization-regeneration systems for applications like syrup, alcohol, etc.

Activated carbon regeneration loss rate <8%, high recovery rate

Fully automated system operation, low manpower requirement

Wide range of treatment: wastewater activated carbon, waste gas activated carbon, decolorization activated carbon, etc.

Wide range of types: granular activated carbon, cylindrical activated carbon, honeycomb carbon, coconut shell carbon, etc.

Multiple process modes available on the MHF with one-key switching, capable of regenerating multiple types of activated carbon

Categorized treatment, high equipment utilization rate, good economic benefits

High operational flexibility, good production capacity scalability. Can be adjusted to "activated carbon regeneration + secondary activation" to increase added value of activated carbon as needed.